Service life of a compressor.

Screw compressors can fail for many reasons just like a reciprocating compressor. Making checks to see that your compressor is performing efficiently is a must, you service your vehicle at regular intervals, inspection intervals should be carried out to prolong the life of your compressor. Periodic oil changes, pressure checks, amperage checks, safety switch testing are just a few simple ways in which you can help prolong the life of your compressor. The majority of screws that we recondition fail mechanically, the odd one or two have ended up being scrapped due to poor maintenance.

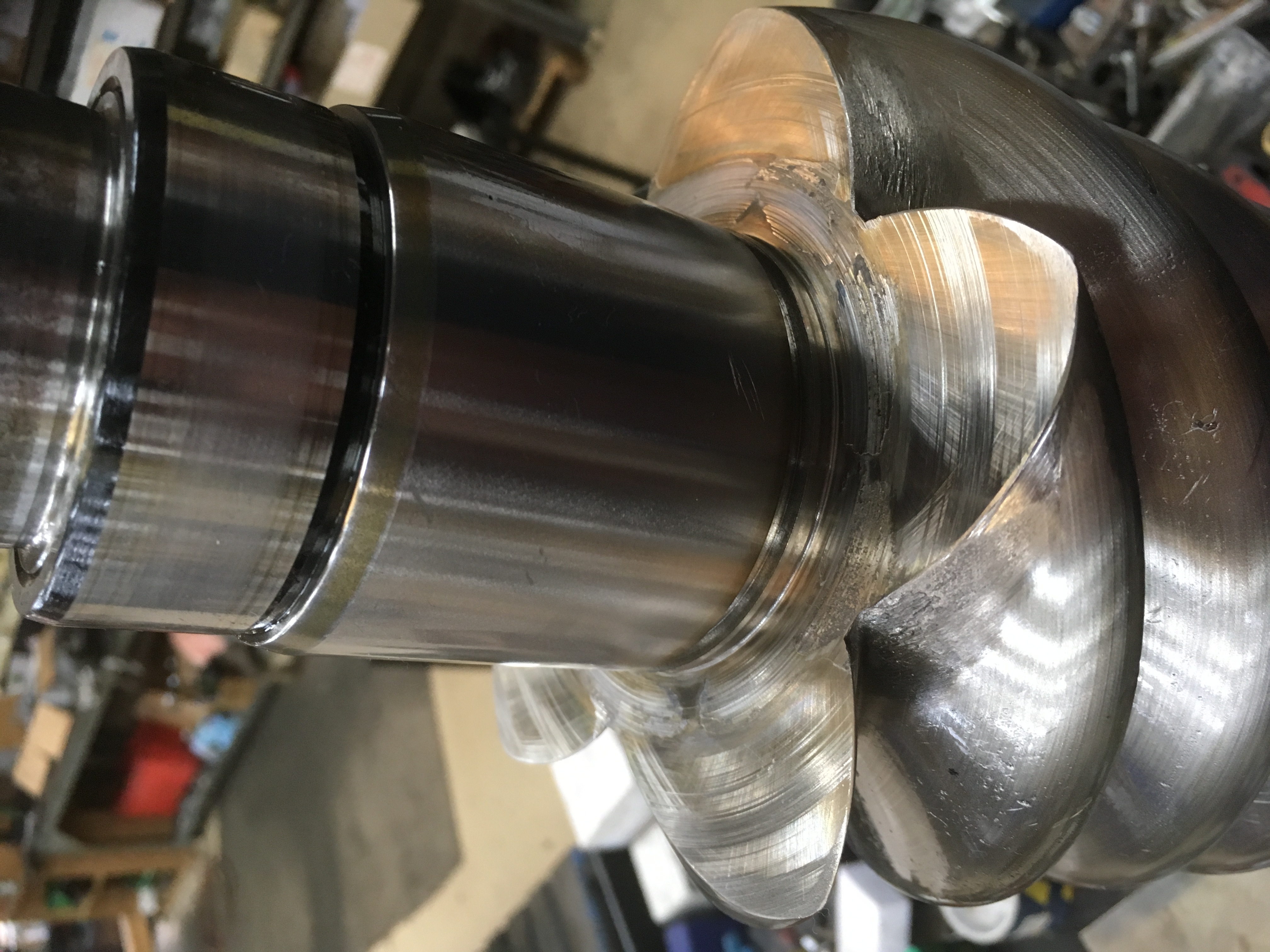

This particular screw compressor had been running longer than its recommended bearing run hours, the customer wasn’t aware that the bearings should be changed after so many hours (each manufacturer uses their own guidelines) this compressor ran until the bearings gave up. The failed bearings caused the male screw to grind into the discharge housing, the end result after stripping down was that the housing & the rotor had to be scrapped, my client had to break the bad news to his client & buy a brand new compressor. If a full inspection had of been implemented at the recommended schedule Screwgle would have remanufactured this compressor and could have stopped this from being an expensive job.

This information is to serve as a general guideline. The information contained is not intended to replace manufacturer's information or guidelines. Screwgle takes no liability for the information contained. It is Scewgle's implicit intention that nothing contained in this guide replaces any past, present or future warranty policy of Screwgle and/or any other manufacturer's equipment.

Please check with your manufacturer's inspection intervals relating to bearing changes.